14th Jan 2019

Closed Cell Polyethylene Foam for Immaculate Towel Displays

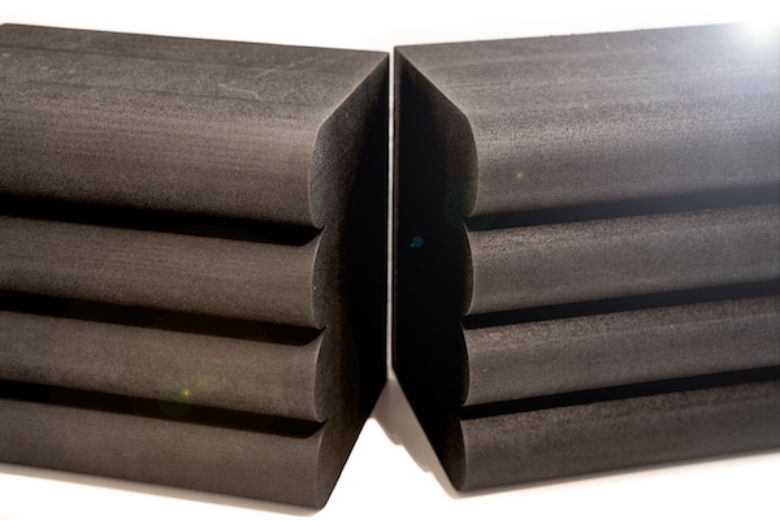

Retail outlets and manufacturers exhibiting in the Homeware and Hospitality sectors are always looking for new ways to delight customers. Closed cell foam can be manufactured and shaped to produce immaculate displays to create uniformity and aspirational presentations for any customer requirements. Whether that’s for towel displays, drapes or bed linen, our closed cell foam blocks can be used for horizontal and vertical displays.

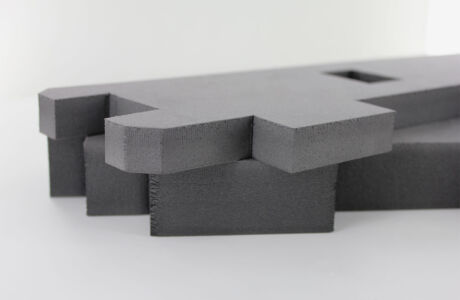

Using a cross-linked closed cell polyethylene foam for towel displays allows for the perfect shape and size to be created in orderly blocks. Fabric is laid and tucked against the rounded, smooth bends of the foam and is easily kept in place by each crease.

It’s incredibly simple to create impeccably neat displays for windows, stores and exhibition stands and doesn’t require any staff training. Only one towel is needed to create the effect and saves heavily on using product for the purpose of display.

They can be used as free standing blocks and do not require any attachments to be fixed to walls or table tops.

Several of the benefits for using closed cell polyethylene foam for displays are:

- It’s lightweight & Cost effective

- The foam can be made into any shape

- Strong and tear resistant

- Non Toxic

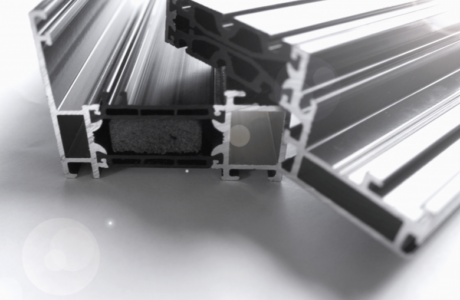

- Waterproof & Chemical resistant

- More durable than some foams

- Easily joined together with a glue gun or heat, if required

- It’s antibacterial

Using foam display blocks shows the product in its best light and it’s formulaic and aesthetically pleasing consistency, sparks the desire in customers to have the same product in their home or hotel.

Zouch have been supplying foam solutions for over 20 years and have a wealth of knowledge and experience when it comes to creating point of display solutions. We can work with you from inception to end solution to create the perfect shape, size and density for your display.

Whatever you’d like to achieve, our expert team can work with you on the design and development of your project, as well as suggesting the very best materials for the job.

As well as die cutting we can split, saw, rout, water-jet cut, butt-weld, laminate, adhere, thermoform or compression mould all of our foams to create even the most complex shapes and sizes.

Speak to us about your latest challenge and we’ll take an unbiased view to help you achieve the very best outcome for your product packaging.