8th Feb 2018

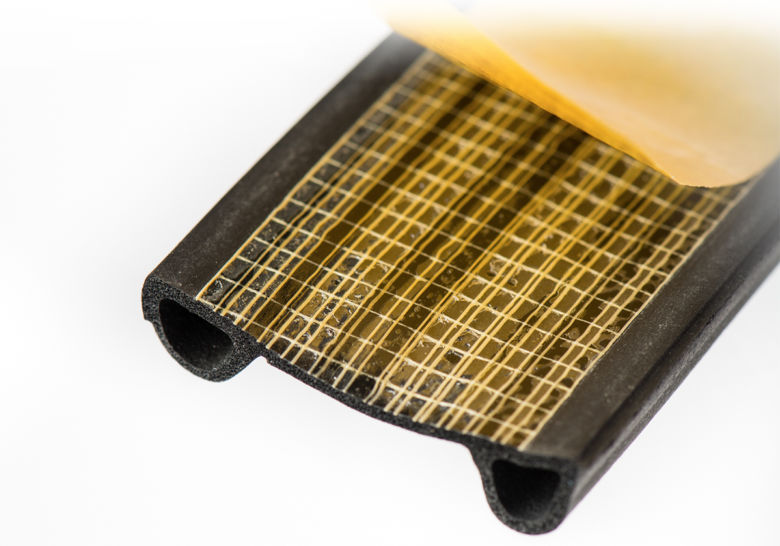

What is Pressure Sensitive Adhesive Tape?

Pressure sensitive is a term used to describe a category of adhesive tapes, when in their dry form, are permanently tacky at room temperature. It’s also known as PSA Tape, Self Adhesive Tape and Self-Stick Tape. The tape material is usually thin to allow for flexibility, with a single or double-sided coating. Its elastic nature means that it can be handled by hand.

PSA tape can bond with the slightest touch depending on the amount of pressure applied by finger or hand. Its adhesive qualities and immediate bonding make it an excellent candidate for many industries with requirements for fastening and joining. Its adhesive remains tacky at room temperature and can be removed from smooth surfaces without leaving behind residue.

What are the types of Adhesive used for PSA Tape?

Solvent-based Adhesive

Solvent-based Adhesive can offer extraordinary chemical resistance, making them well-suited for use in environments where exposure is possible, such as the outdoors, industrial appliances or exposure to caustic fluids. Solvent adhesive tape can also function at low and high temperatures, making them extremely versatile. They are strong and have a superior shear and peel strength.

Water-based Adhesive

Water-based Adhesives are often used for packaging, labelling, and tapes. They can be made in both permanent and removable PSAs. They work across a range of surfaces and substrates.

Hot Melt Adhesive

Hot Melt Adhesives (HMAs) are most commonly used for tapes and labels due to their ability to form a bond under light pressure at room temperature. There are two types of HMAs for the use in tape which are Tamper Evident (for permanent bonds) and Peel-able Sealing (for non-permanent bonds). HMAs often require tackifiers and oil modifiers to achieve the desired adhesive performance.

Rubber-based Adhesive

Rubber-based adhesive is the most cost effective PSA and offers quick stick capabilities and highly flexible bonds. They bond to low-energy surfaces and are ideal for low or room temperature applications.

What are the advantages of using PSA Tape?

- PSA Tape does not require heat, water or other solvents to activate the adhesive. They are tacky at room temperature in their dry form.

- Its permanent tackiness for adhesion easily bonds diverse materials such as plastics, wood, glass, paper, metal, and more.

- It can be easily applied with varying degrees of pressure with a finger or hand.

- It’s made of thin, light material for flexibility and ease of application.

- Reduces the assembly time of fasteners and improves productivity.

- Different levels of shear resistance.

- Gives a superior cosmetic finish and provides uniformity.

What are common industries for Pressure Sensitive Adhesive Tape?

- Medical

- Design and Engineering

- Automotive and Transport

- Electronic

- Optical

- Container Construction

- HVAC

- Industrial

- Furniture

- Packaging

Why choose a PSA Tape over alternative Adhesive Tapes?

Alternative adhesive types are hot melts, sprays, liquids, and light-cure adhesives.

- Non PSA hot melt adhesive requires specialised equipment capable of melting and delivering the adhesive.

- Spray adhesives are often solvent-borne systems applied to the substrate with air pressured mists.

- Liquid adhesives require a brush or roller for application and coating.

- Light-cured adhesives need to be exposed to UV or visible light.

- Application and surface temperature will also need to be accounted for when it comes to other adhesive tape options.

PSA Tape is applied by finger or hand with pressure. It is also more economical when considering aspects such as ongoing quality inspection and in-house application experts. It’s also not as easy to tailor alternative adhesives to specific specifications.

Choosing the right PSA Tape for your project

Application is a big factor when choosing the right PSA Tape for your project and it’s important to consider elements such as the condition of substrates, texture of substrate, temperature of application, temperature during use, exposure to light, expected usage, and how the product is applied, are to name but a few.

At Zouch, we have an unrivalled range of pressure-sensitive self-adhesive tapes that are handpicked from the world’s leading manufacturers. We’re able to deliver them as reels, spools, master logs, sheets and die-cut pieces, both single-sided or double-sided.

We have an expert technical team who will give you unbiased advice and support. Get in touch with our team about your challenge and we will help you to determine the correct PSA Tape for your project. We also offer a fast and free sample service to ensure that you’re happy with the quality of PSA Tape.